A Brief Look at Insert Molding

Insert molding is a modern manufacturing method that has become very useful and flexible, helping many different industries in many ways. The goal of this article is to give a full picture of insert molding by talking about what it is, how it has changed over time, and how important it is in modern manufacturing.

What is Insert Molding

Additive molding, also called overmolding or two-shot molding, is a unique way to make things that blends the best parts of injection molding with the addition of secondary parts. A pre-shaped insert, like a metal, plastic, or electronic part, is put into a mold hole using this method. Then, a second material, usually a thermoplastic polymer, is injected around the insert, making a strong bond between the two. This process makes a multi-material product that is highly integrated and blends the desired properties of the insert and the molded material in a way that looks and works great.

A Brief History of Insert Molding and How It Has Grown

The first time insert molding was used was in the early 1900s, when the injection molding process was first used. Insert molding was created when makers saw that secondary parts could be directly molded into the main parts. This was possible as technology improved. In the 1950s and 1960s, the process became very popular, especially in the electronics and auto industries, where being able to combine different materials and make products work better became more useful.

The insert molding method has come a long way over the years thanks to improvements in mold design, material science, and automation technologies. Insert molding has become a lot more useful since computer-controlled injection molding tools, special mold geometries, and advanced molding materials came out. This method is now used in many different fields, ranging from consumer electronics and medical devices to aerospace and car parts.

How and why it’s important in modern manufacturing

You can’t say enough about how important insert molding is to current manufacturing. This process is very flexible and has many uses that have made it an important tool in many fields:

Better Product Function: Insert molding lets makers make products that are better at what they do by combining different materials. These products can have better mechanical properties, last longer, and include electronic parts or sensors.

Flexibility in Design: Using pre-formed inserts in the molding process gives designers more freedom in how they make goods, so they can make complex, unique, and customized ones that meet the needs of specific markets.

Cost-Effectiveness: Insert molding can often save money by cutting down on the number of steps needed for assembly, lowering the need for extra work, and speeding up the whole production process.

Better efficiency: Adding insert molding to automatic production lines has made production more efficient, cut down on the need for labor, and improved quality control measures.

Sustainability: Being able to combine different materials into a single, cohesive part can help make manufacturing more environmentally friendly because it cuts down on the need for separate parts and makes it easier to recycle goods when they’re no longer useful.

Many different types of businesses use insert molding, such as the automotive, electronics, medical device, consumer goods, and aerospace industries. It is used to make parts for the car industry, like door handles, safety systems, and parts for the fuel system. Insert molding is used in the electronics business to make housings, connectors, and enclosures for a lot of different devices that are all built in. In medicine, the process is used to make surgical tools, parts for prosthetics, and systems for delivering drugs. Insert molding is very flexible, which keeps leading to new ideas and opening up new manufacturing options.

How Insert Molding Works: The Basics

Insert molding is a unique way to make things that blends the best parts of injection molding and component assembly. During the injection molding process, a metal, plastic, or clay part that has already been made is put into a plastic part using this method. The end result is a composite structure that combines the desired properties of the insert and the molded plastic. This makes it possible to make complicated, useful parts in a single, quick step.

A Look at the Process

Getting the Insert Ready: The insert, which can be made of different materials, needs to be carefully prepared before it is put into the mold. To make sure the insert sticks well to the formed plastic, this could mean cleaning, treating the surface, or adding a coating. The insert is often made with undercuts or protrusions that make it easier for the two materials to fit together mechanically.

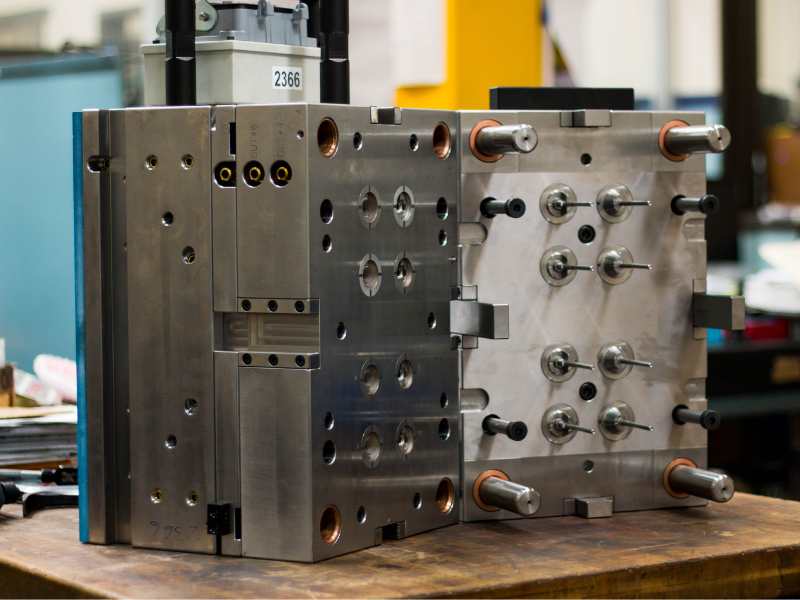

Putting the Insert in the Mold: The ready insert is then put into the mold hole, either by hand or by a machine. Putting the insert in place is a very important step because it needs to be perfectly lined up to get the end shape you want and the best distribution of the molten plastic around the insert.

Putting the Plastic in the plastic Mold: Next, the molten plastic is poured into the mold hole, covering the insert. Carefully managed flow of the plastic around the insert keeps air from getting trapped and makes sure the whole surface of the insert is covered. To get the material traits and part quality that are wanted, the pressure and temperature of the injection process are carefully watched.

After the plastic has hardened, the mold is opened and the part that was molded is removed. The cooling stage is an important step because it makes sure that the part solidifies properly and stays the same size. The part that was released is then checked and, if needed, goes through any other post-processing steps.

Insert Types That Are Used

Inserts Made of Metal: In insert casting, metal inserts like those made of steel, aluminum, or brass are often used. These inserts give the end part strength, good thermal conductivity, and protection to corrosion. Metal inserts are often used in places where strength is needed, like in car parts, home appliances, and industrial machinery.

Plastic Inserts: These are made from thermoplastics or thermosets and are used when the end part needs to have properties that are a mix of plastic and the insert material. Plastic inserts can be used to make complicated shapes, perform specific tasks, or add artistic elements to a molded part.

Inserts Made of Ceramic: Inserts made of ceramic, like those made from alumina, zirconia, or silicon carbide, have special qualities like being able to withstand high temperatures, conducting electricity, and not reacting with chemicals. In the electronics, aerospace, and medical industries, for example, where the finished part needs to be able to handle high temperatures or harsh environments, these inserts are often used.

Different Types of Materials: Insert molding can use a lot of different types of materials, not just metal, plastic, and clay. These include wood, glass, and natural fibers. The type of material used for the insert depends on the job, like what kind of mechanical, thermal, or aesthetic qualities the finished part needs to have.

Compared to the old way of doing injection molding

Insert molding is better than standard injection molding in a number of ways:

Better Part Function: Adding inserts to a molded part can make the whole thing work better by giving it extra features like higher strength, better electrical or heat conductivity, resistance to corrosion, or certain surface finishes.

Less time and money spent on assembly: Insert molding combines several parts into a single molded part, so there is no need for separate assembly steps. This cuts down on manufacturing time and costs.

Increased Design Flexibility: Being able to use different insert materials in the molded part gives designers more options, which lets them make more complicated and personalized products.

Better Quality Control: Placing the insert in the mold hole in a controlled way can make the final part more consistent and reliable, lowering the chance of flaws or differences.

Overall, the Basic Principles of Insert Molding show how flexible and useful this method of making things is. Manufacturers can make high-quality parts that can do more than one thing by carefully adding pre-made inserts to the injection molding process. These parts can be used in a variety of industries as their needs change.

An in-depth look at the materials used in insert molding

When insert molding, one of the most important things to think about is how well the materials will work together. The material used for the insert has to be strong enough to handle the high temperatures and pressures of the injection molding process, as well as the chemical and physical loads that will be put on the part when it is used. Inserts are often made of metals like steel, aluminum, and brass, as well as designed thermoplastics like nylon and polyetheretherketone (PEEK). Go to PEEK injection molding to know more.

Metallic inserts are often used in places where strength, longevity, and resistance to heat are important. For structural stability, load-bearing capacity, and the ability to handle high temperatures, these inserts can be used. But it can be hard because the insert shape is complicated and it needs to be perfectly aligned during the molding process. To make sure the bond is strong and reliable, manufacturers must carefully think about how the metal piece and the polymer around it expand and contract when heated or cooled.

On the other hand, thermoplastic parts give you more design options and are easier to add to the injection molding process. It is easy to add features like threads, snap-fits, and living hinges to these inserts, which can be carefully shaped to make complicated shapes. The way thermoplastic pieces expand when heated is often more like the way the surrounding polymer expands, which makes the bond stronger and more reliable. Thermoplastic inserts can also have functional parts added to them, like electrical contacts or sealing features, which makes the finished product even more useful.

It is also very important to choose the right polymer material for the formed part when insert molding. It’s important that the polymer and filler material can stick to each other and mix well so that the bond is strong. In insert molding, industrial thermoplastics like polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and glass-filled nylon are often used. The mechanical, thermal, and chemical qualities of these materials can be changed to fit the needs of the application.

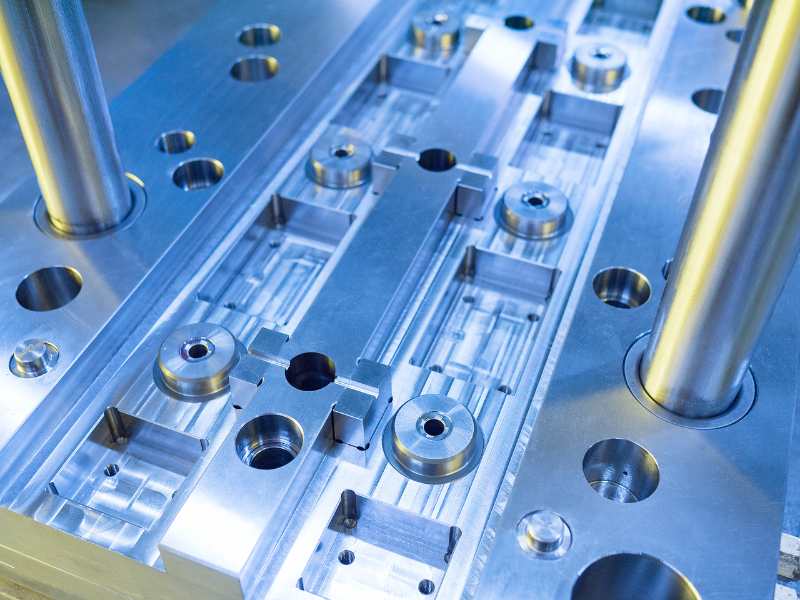

Along with the right material, the insert’s form and the shape of the mold are also very important to the success of the insert molding process. The surface finish, undercuts, and mechanical interlocks of the insert, among other things, can have a big effect on how strong and stable the bond is between the insert and the molding part. To make sure that high-quality insert-molded parts are consistently and reliably made, mold design factors like gate placement, cooling channels, and part ejection mechanisms must be carefully designed.

Because insert molding can be used in many different fields, from automotive and aerospace to electronics and medical products, it is very popular. Because it lets functional parts be added, structural performance is improved, and complex shapes can be used, this method of manufacturing is very useful for product designers and engineers.

With more advanced technology and a greater need for new, integrated goods, it will become even more important to understand the materials and design issues involved in insert molding. Manufacturers can get the most out of insert molding by carefully choosing the right materials and making the most of the manufacturing process. This lets them make high-performance, reliable, and cost-effective goods that meet the changing needs of the market.

A Look at the Different Types of Insert Molding Methods

Overmolding, which is also called two-shot or multi-shot molding, is one of the most common ways to use insert molding. If you use this process, you put the insert part into the mold cavity and then inject plastic around it. This makes a strong bond that lasts. This method works especially well for making seals, gaskets, and electrical parts that are enclosed. The plastic material protects, keeps the structure together, and looks good.

Co-molding is another popular insert molding method. It involves injecting two or more materials into a single mold at the same time. This method creates complicated parts out of more than one material in a single step, so there is no need for extra building steps. When making things like toothbrush handles, co-molding is often used. The rigid plastic body is mixed with a soft, overmolded grip to make the item more comfortable and easy to control.

One type of insert molding that works best for bigger or more complicated insert parts is compression molding. This method involves putting the plug into the mold and then compressing the plastic around it to make a strong, one-piece part. In the manufacturing of car parts like steering wheel inserts or instrument panel components, this method is often used. The insert either strengthens the structure or adds functionality.

In insert injection molding, on the other hand, different materials are injected one after the other into the same mold hole. In this method, the insert part is put into the mold first, and then the main plastic material is inserted around it. After this, a second material is injected. This can be a cover for looks, a feature that does something, or a layer that protects. Often, this method is used to make things like computer housings, where the insert part can help with structure or protect against electricity.

Along with these tried-and-true methods, new types of insert molding have come up in the last few years to meet the changing needs of different businesses. In-mold assembly (IMA), for example, mixes the insert molding process with the assembly of extra parts. This makes it possible to make highly integrated, multifunctional parts in a single manufacturing step. Insert overmolding, which combines insert molding and overmolding, also makes it possible to make complicated parts out of more than one material that look better and work better.

Each of these insert molding methods has its own benefits and is best used for certain tasks and situations. Which method to use depends on things like how complicated the part is, what materials are used, what mechanical and functional qualities are wanted, and how much the part needs to be made and how much it costs. The need for new, multifunctional products keeps growing. The insert molding process is still one of the most important tools in modern production because it makes it possible to combine different materials and functions into a single, cohesive part.

Insert molding has benefits like making product design better and manufacturing more efficiently.

One great thing about insert casting is that it can make the production process go more quickly. Insert molding gets rid of the need for time-consuming and hard-to-do assembly steps by combining multiple parts into a single, combined part. This combination not only cuts down on the number of parts needed, but it also lowers the chance of mistakes and speeds up production as a whole. Now, manufacturers can get better product consistency, shorter lead times, and lower running costs.

Another great thing about insert molding is that it can be used to combine different types of materials. With this method, designers can mix many different types of materials, like metals, plastics, and electronics, into a single, solid part. This adaptability lets makers make complicated, multipurpose goods that meet the changing wants of the market. For example, insert molding is used in the car industry to combine electronic sensors, metal inserts, and plastic housings into a single, high-performance part that makes the vehicle work better and have more features.

In addition, insert molding gives manufacturers more design options, so they can make complex, custom-made goods that meet their customers’ exact needs. Because it lets you mix different materials and use complicated shapes, insert molding makes it possible to create new products that would have been hard or impossible to make with traditional methods. This design freedom leads to better product performance, looks, and the total user experience.

Insert molding not only looks better, but it also lasts longer and is more structurally sound. When the materials are molded together, they form a strong bond that lasts for a long time. This makes the product strong and durable enough to handle the wear and tear of everyday life. The improved structural stability is especially helpful in places where safety and dependability are very important, like in the medical and aerospace industries.

Additionally, insert molding saves a lot of money because it doesn’t need any extra steps like building, welding, or fastening. Insert molding gets rid of these extra steps in the manufacturing process by combining several parts into one part. This lowers production costs and increases total profitability.

Finally, insert molding has many benefits, such as being efficient, allowing for better design, integrating materials better, and saving money. Because insert molding can be used for many different things, it is becoming more and more popular as a way to make products because businesses need new, high-performance, and cost-effective products. Adopting this cutting-edge technology can help companies come up with new products, give them an edge over their competitors, and give their customers better value overall.

An essay on the pros and cons of insert molding

Even though insert molding has many benefits, it also has some problems and restrictions. This essay will talk about the main problems and restrictions of this method, focusing on the things that designers and makers need to think about when using insert molding.

The fact that insert molding is a complicated process is one of its main problems. Insert molding works best when you have exact control over many factors, such as the compatibility of the materials, the placement of the inserts, and the design of the mold. If you don’t keep these factors under control, they can cause a number of problems, such as the insert coming loose from the plastic part or not being fully encapsulated.

Another big problem is that the inserts have to be placed with very tight specs and in the right place. To make sure that the parts are all the same quality and that the finished product works the way that was wanted, the insert has to be placed very precisely inside the mold cavity. Any misalignment or movement of the insert can cause changes in the width of the wall, unequal stress distribution, or even failure of the part.

Also, the plastic and insert materials must have very similar thermal expansion and shrinkage properties so that the finished part has the least amount of residual stresses and possible deformation. Having different amounts of these qualities can cause problems like warping, cracking, or delamination, which can hurt the insert-molded part’s strength and performance.

Besides the technical problems, insert casting also has problems with cost and transportation. Insert molding usually needs more complicated and pricey tools than regular injection molding because it needs to be able to hold the extra insert parts and make sure they are placed correctly and fit together properly. This higher cost of tools can be a problem for some makers, especially when they are making prototypes or small amounts.

Also, the insert molding process can take longer and require more work than other ways of making things because it usually has extra steps like insert preparation, positioning, and checking. These things can change how cost-effective and efficient the process is generally, which can make it less appealing for some uses or production situations.

Another problem with insert molding is that it can only work with a small number of materials. Not all materials can be used together, so it’s important to think carefully about which plastic and filler materials to use to make sure the bond works well. When two materials don’t work well together, they can stick together poorly, separate, or even react chemically, which can hurt the end part’s performance and durability.

Last but not least, the complexity of the insert molding method can make it hard to check and control the quality. Because the filler and the plastic part are joined together, it can be harder to find flaws or errors in the finished product. To make sure that high-quality insert-molded parts are always made, you might need to use special checking methods and quality control measures.

In conclusion, insert molding has many benefits when it comes to integrating parts and making them work better, but it also has some problems and restrictions that designers and makers need to be aware of and work around. To use insert molding correctly, you need to fully understand the process and think about all the things that can affect the quality and performance of the final product. These things include how expensive it is, how well the materials work together, and how complicated the process is.

How Insert Molding Is Used

The automotive business is one of the main places where insert molding is used. Dashboard panels, door handles, and center consoles are all examples of automotive parts that need to have metal inserts, electrical circuitry, and other useful parts built in. Manufacturers can make these complicated parts in a single, streamlined step, which cuts down on assembly time and costs while keeping exact specs and high-quality finishes.

The electronics business is another one that has used insert molding a lot. Insert molding is used by companies that make electronics like smartphones and home appliances to add parts like switches, sensors, and connections without changing the way the product looks. Small, light, and long-lasting electrical assemblies that can handle the wear and tear of daily use can be made using this method.

Insert molding is a very important part of making medical equipment and implants in the medical and healthcare fields. Insert molding gives precise and adaptable solutions for a wide range of delicate uses, from orthopedic devices that use metal parts for strength and stability to drug delivery systems that use special drug-eluting inserts. Also, the fact that biocompatible materials can be molded straight onto inserts makes sure that these medical devices are safe and effective.

The ability of insert molding to shape things has also helped the building and infrastructure businesses. Through the insert molding process, structural parts like reinforced concrete walls or composite building materials can have metal inserts or other strengthening elements added to them. These building materials are stronger, last longer, and work better overall because of this integration. They are better prepared to handle the challenges of the built world.

There are many aluminum casting parts are used for insert molding, you can go to die casting mold page to know more about die casting.

In addition to these fields, insert molding is used in a lot of consumer goods, such as toys, sports equipment, and home items. Being able to combine different materials and parts without any problems in one part lets designers make new, useful, and aesthetically pleasing goods that meet customers’ changing wants and needs.

Insert molding is also used to make specialized industrial parts like electrical plugs, hydraulic fittings, and machinery parts, which shows how flexible it is. In these situations, the method lets you make complicated, very accurate parts that meet strict requirements for safety and efficiency.

As technology keeps getting better and products get more complicated, insert molding becomes more and more important in modern manufacturing. Engineers and creators can push the limits of what is possible with this new process. It opens up new ways to create new products, improve their performance, and cut costs. By combining different materials and parts in a seamless way, insert molding has become an important part of high-quality manufacturing. It helps make better goods that meet the changing needs of the global market.

Things to Think About When Designing Insert Molding

First, picking the right filler material is the most important thing you can do. The insert can be made of metal, plastic, ceramic, or any of a number of other materials. It must be compatible with the shaping plastic in order for the bond to be strong and reliable. To lower the risk of delamination or other structural problems, things like thermal expansion coefficients, surface roughness, and chemical compatibility must be carefully looked at.

The style of the insert itself is just as important. Because of its form, size, and geometry, the insert can have a big effect on how the molten plastic flows during the injection process. It’s important to think about where the insert goes in the mold and if there are any features or protrusions that might make it harder for the plastic to cover it completely. The right shape of the insert can also help get rid of air pockets quickly and keep the surface from getting sink marks or other flaws.

Another important part of the success of an insert molding job is the design of the mold itself. It is necessary to design the mold so that it can hold the insert securely and accurately. In this case, special features like pins or tracking devices may need to be added to keep the insert in place during the injection process. When making the mold, the flow patterns of the molten plastic must also be taken into account. This means that the gating system and runner design must be optimized to get even filling and reduce the amount of stress left in the finished part.

Along with the physical design, the process parameters of the insert molding action need to be carefully thought through as well. The quality and efficiency of the final part can be greatly affected by factors like the melt temperature, the injection pressure, and the cooling time. It might take a lot of trying and tweaking to find the best process parameters for a certain material and insert combination.

It’s also important to think about post-processing during the design step. For example, you might need to do secondary operations like trimming, deburring, or surface finishing. It’s important to think about how these extra steps will affect the general cost and lead time of the manufacturing process when planning the whole project.

Lastly, it’s important to think about what the insert-molded part will be used for and how well it needs to work. To make sure the design meets all the safety and performance standards, it’s important to carefully look at things like mechanical load, weather exposure, and government rules. It might be necessary to simulate and try the design to make sure it works well for the purpose it was made for.

In conclusion, there are many things to think about when designing for insert molding, and you need to know a lot about materials, mold design, and manufacturing methods. Designers and engineers can make the insert molding process work better by paying close attention to these factors. This will lead to high-quality, long-lasting, and cost-effective products that meet the needs of today’s businesses. More and more people want new and integrated solutions. Because of this, it will become even more important to create insert molding with care and attention to detail.

We are one of top 10 mold manufacturers and aluminum die casting manufacturers in China, if you are looking for any type of injection molding service, contact us.